High-voltage Genset

High-voltage genset is mainly used to meet the electricity demand of high voltage equipment, long-distance electricity transportation needs and high-power electrical load for parallel operation. With growing capacity requirements on diesel genset as a standby power supply, synchronization operation of multiple high-power diesel gensets will be needed to meet the load requirements.

Moreover, the gap between engine room load and the actual load is growing, using multiple traditional low-voltage diesel gensets operating and transporting in parallel is exposing defects on safety and cost inputs. And high voltage gensets turn out to be a great choice.

Structure and characteristics of high-voltage genset are as follows,

1. Engine: Generally, a single genset is required to have a power of 1000KW or above, for which Cummins, Perkins and other brand engines are applicable. There is no difference with low-voltage gensets.

2. Generator: selected according to different voltage levels. Major brands: Leroy Somer, STAMFORD. Generation principle is the same with that of low-voltage motors, but the structure is quite different from the low-voltage generator.

3. Connection: reliable and safe coupling connection of double bearing generators

4. Paralleling control system: typically includes a main controller and synchronizing devices, etc., and can be optionally equipped with DSE or COMAP control system and differential protection. It is basically the same with low-voltage paralleling control system.

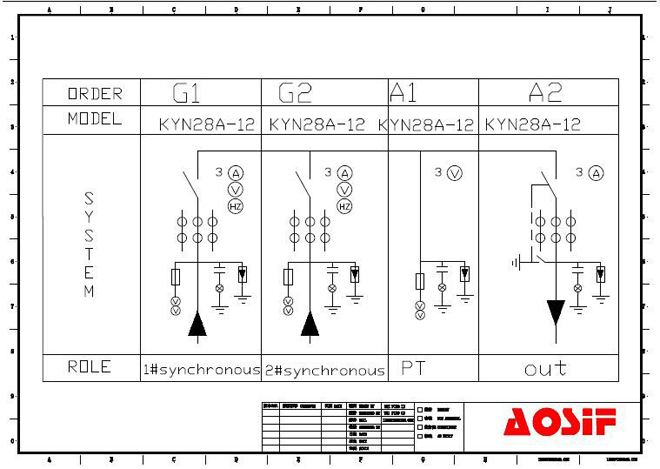

5. High-voltage switchgear: general uses KYN28 type output cabinet. It is configured with raw-out vacuum breaker, integrated security systems and DC operation. It accepts commands from paralleling controller and quickly executes, feedbacks operation status, feedbacks fault information and outputs power.

6. PT cabinet: for sampling of electric parameters of busbar.

7. Neutral resistor: used for the generator neutral protection and single phase earth fault protection, providing a smaller earth current, preventing large current from impacting generator windings, increasing the configuration of zero sequence CT, accurate measurement of zero-sequence current and tripping down in a timely manner when a failure occurs to protect the security of the power system.

8. DC panel (optional): provides DC operating power supply for the high-voltage switches, usually supported by feeder cabinet manufacturers.

Most of the high-voltage gensets are used in metallurgy enterprises, airports, data centers and other standby power supply systems. With gensets’ output voltage set to be consistent with the original power system voltage, they can be directly connected to the power supply system, eliminating the need for big equipment investment in power supply and distribution systems.

Besides, the high output voltage and low output current of gensets have also saved the costs of main busbars and cables and minimized the power loss during power transmission, so it is suitable for long distance transmission.

Generally, 220Kv voltage is adopted for transmission over 200-300km, 110KV for 100km, 35KV for 50km and 10KV or 6.6KV for 15-20km.Typically, multiple high-voltage gensets are set for parallel operation in order to meet the capacity demand. The system diagram is as follows: two gensets in parallel

![]()

![]()

![]()

![]() 闽ICP备18021334号

闽ICP备18021334号